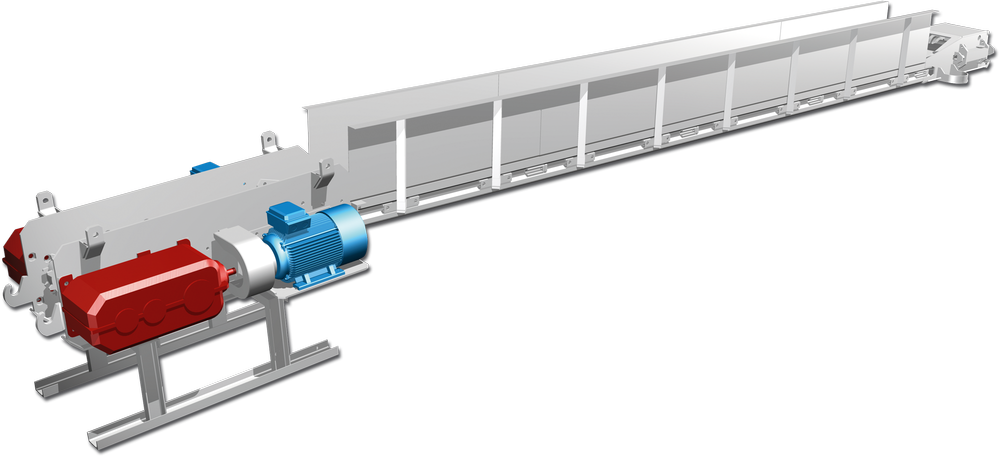

The scraper conveyor can be supplied in various drive versions. Depending on the number and power of installed drive units, type of drum and the method of conveyor installation.

The conveyor is designed for output haulage over short distances from coal, coal and rock, as well as rock horizontal or inclined headings and from shortwalls, open-ends and low-output longwalls.

The maximum inclination angle of the conveyor is ±35°.

Depending on the needs of the customer and haulage method, the conveyor can be set up in the different ways:

The scraper conveyor may be used in underground mines in the fields categorised as a, b or c class of methane explosion hazard as well as A or B class of coal dust explosion hazard.

| Power | 1x15, 2x12, 1x22, 2x22 kW – with a 6-teeth drum |

1x15, 2x12, 1x22, 2x22 kW, 1x30, 2x30 kW – with an 8-teeth drum |

||||

| Max efficiency | 300t/h | |||||

| Chain speed | 0,6-0,8m/s | |||||

| Chain type | 18x64 | |||||

| Chain spacing | 320mm | |||||

| Scrapers spacing | 512 | 1024 | ||||

| Transmission type | PPL-22 | PPL – 14/22-P | AP 400-22/30 | |||

| Chute width | 440mm | |||||

| Chute height | 180mm | |||||

| Chute length | 1500mm | |||||

Types of scraper conveyors: