The company has implemented a Quality Management System according ISO 9001, ISO 14001 and ISO 45001

The company has realized a project under the Sectoral Operational Programme

"The Increase of Economic Competitiveness in 2004-2006"

co-funded by European Regional Development Fund.

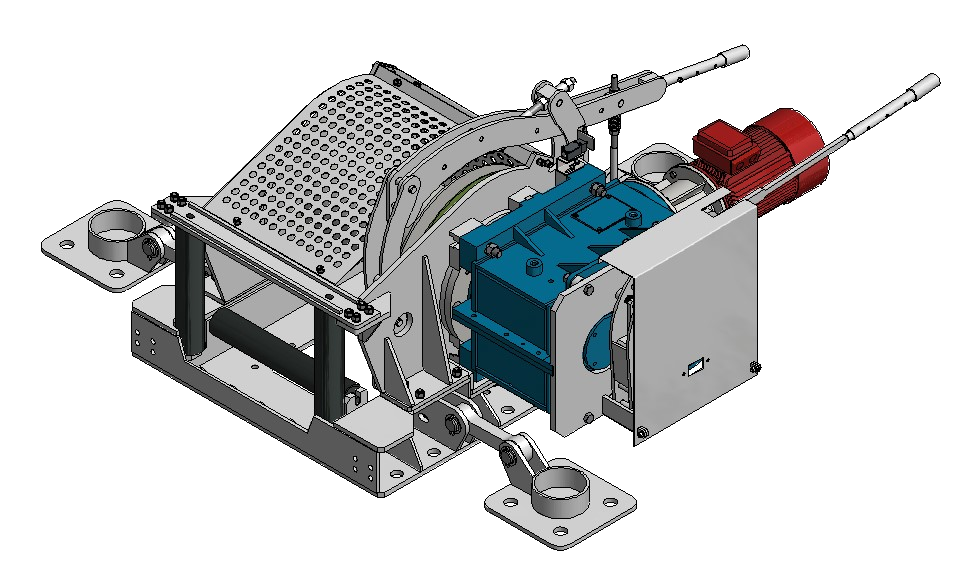

The winch VACAT/15-30/C can be operated in underground headings of mining facilities, including non-methane and methane fields, with a "a", "b" or "c" degree of methane explosion hazard and in fields classified as "A" or "B" class of coal dust explosion risk. The winch VACAT/15-30/C it is used to move heavy parts of mining machines and devices along the floor during work in mining excavations, as a supporting device as well for the reinforcement and to help with excavation closings. Can be used to extract and insert powered support sections, as well as other elements of machines and devices in mining excavations. The winch could be used for pulling transformers, various types of heavy elements of electrical apparatus and as an auxiliary device for reloading heavy elements, as well as for transport work where high pulling force is required. The Winch can be operated in mining with a slopes that prevents the pulling elements from rolling away by itself. The Winch can be used in wheeled transport systems to move wagons along the tracks in horizontally places with inclination not bigger than ±4o.

| Data for the Winch VACAT/15/C | |

| Draw-bar pull on the first coat (drum diamater Ø 406mm) | 14,2 kN |

| Draw-bar pull on the first coat (drum diameter Ø 510mm)) | 11,4 kN |

| Draw-bar pull on the last coat | 7,5 kN |

| Data for the Winch VACAT/30/C | |

| Draw-bar pull on the first coat (drum diameter Ø 406mm) | 28,0 kN |

| Draw-bar pull on the first coat (drum diameter Ø 510mm) | 22,4 kN |

| Draw-bar pull on the last coat | 15,0 kN |

| Data (altogether) for the Winch VACAT/15-30/C | |

| Cable speed (on the first and last coat for the drum Ø 406mm) | 0,9÷1,7 m/s |

| Cable speed (on the first and last coat for the drum Ø 510mm) | 1,1÷1,7 m/s |

| Maximum angle of road inclination | ±4° for rail transport to the limit angle of the self-rolling slope (floor transport) |

| Working width of cable drum | typicall 670 mm (400mm-1000mm) |

| Drum diameter | Ø 406mm lub Ø 510mm |

| The diameter of the drum rims | Ø800 mm |

| Rope winding method | undershot |

| Geabox | GVO-30 |

| Gear ratio | 35,2 |

| Input revolutions | n=1500 rev/min |

| Winch operation control | Maneuvering brake installed on the movable yoke of the gearbox GVO-30 |

| Braking system | manual auxiliary brake on the cable drum |

| Device dimensions (without the feet): | Length: 2540 mm, Width: 1757÷2357 mm (typowe 2027mm), Height: 1180 mm |

| Weight | 3370 kg (typicall) |