The company has implemented a Quality Management System according ISO 9001, ISO 14001 and ISO 45001

The company has realized a project under the Sectoral Operational Programme

"The Increase of Economic Competitiveness in 2004-2006"

co-funded by European Regional Development Fund.

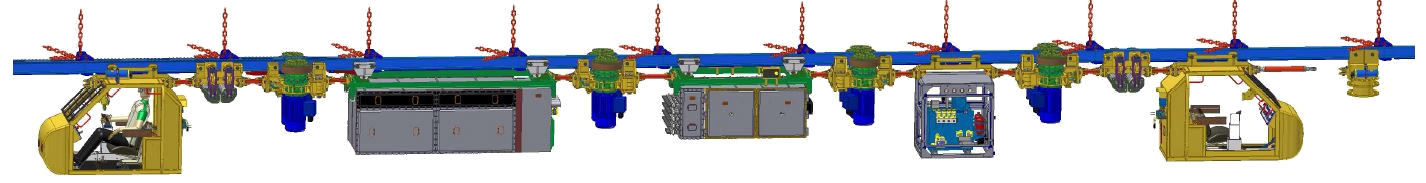

Suspended Railway GAD-1 is designed for personnel transport on inclinations up to ± 25° and material transport on inclinations up to ± 30°. It can be operated in underground excavations of mining facilities, in methane and non-methane environment, including headings with “a”, “b” or “c” methane explosion hazard degree and class A and B coal dust explosion hazard. If the concentration of methane in the surrounding atmosphere exceeds 2%, the Railway will be automatically turned off until the concentration of methane decreases to acceptable level. Suspended Railway GAD-1 is configurable with 2, 3 or with 4 driving carts, depending from the required pulling force. In addition, it can be used in the configuration called "fixed" or "unhooked". The figure above shows an example of a fixed Railway configuration with a maximum number of four driving carts. Railway GAD-1 is equipped with fully electric drive units. Railway GAD-1 is designed to transport personnel and material along suspended, friction or rack rails, with inclinations up to 30°. The Railway driving carts have built-up cog wheels above the friction wheels, through which the device can generate more tractive force at a reduced driving speed.

| Friction wheels tractive force – max. for 4 driving carts | 80 kN +10% |

| Cog wheels tractive force – max. for 4 driving carts | 120 kN +10% |

| Minimum Static Braking Forc | 180 kN |

| Speed with friction driv | 2 m/s |

| Speed with cog wheel drive | 1,4 m/s |

| Maximum slope of the friction or cog type running rail | ± 30° |

| Length of the device with four drive carts | 17,9 m |

| Height measured from the running rail | 1,36 m |

| Width | 1,06 m |

| Weight of the device with four drive carts | 12 t |

| Permissible temperature in the working area | +5°C do +35°C |

| Rated speed of electric motors | 900 rpm |

| Rated power of a single motor in one cart | 10,8 kW |

| Rated torque of the motor in one cart | 114,6 Nm |

| Rated motor power of the hydraulic system | 2,2 kW |

| Acceptable battery charging level | depends on the route |

| Alarm battery level | 100,00% |

| Battery rated voltage | 265V DC |

| Maximum battery power | 160 kWh |

| Nominal battery current | 4 x 80A |

| The supply voltage of electric motors of drives SMwsPA132M6 | 152V AC |

| The supply voltage of the hydraulic motor dSLg100L4A-1 | 152V AC |

| Nominal drain current of drive motors | 45A |

| Nominal hydraulic motor drain current | 12,7A |

| Maximum current of auxiliary circuits | 24V (DC), 22A |

| Intrinsically safe voltage | 12V (DC) |